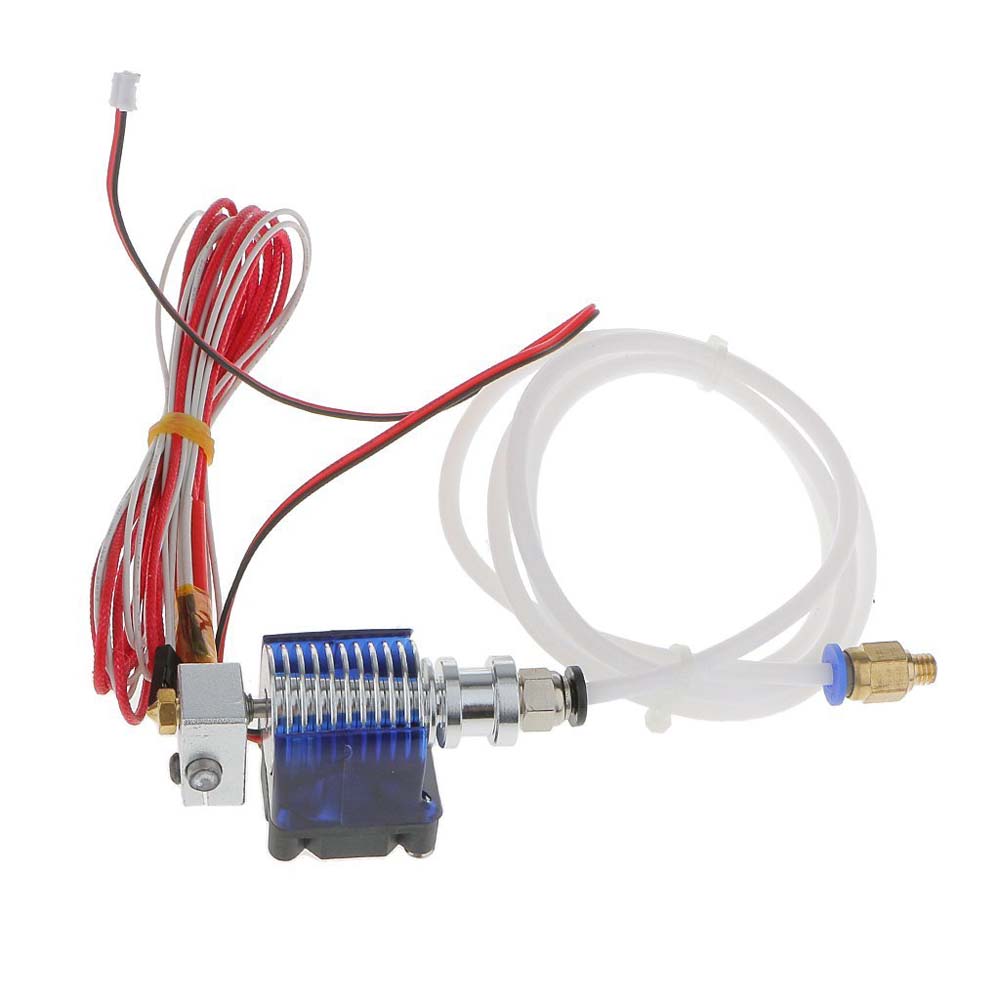

Description

Fully assembled all metal hotend with cooling fan for use with Direct or Bowden Extruders

- There’s a consistent 2mm of space for the filament from the moment it goes into the PTFE tube, to when it reaches the nozzle. This results in almost zero jamming chances.

- Thermistor: The all metal v6 has a simple screw in method for securing the Thermistor, instead of using tapes or messy silicone/adhesives.

- Heater Cartridge: An increased point of contact between the heater block reduces the power required and improves heat up times and puts the heater closer to the nozzle.

- Fan Shroud: Has a custom injection molded fan shroud. This makes for a much easier and cleaner install. The fan shroud color is random

- Nozzle: options 0.3MM / 0.4MM / 0.5MM : The most important improvement on the J-Head v6 is the new compact design, The thread of the nozzle: M6 thread

The v6 Hotend adds a second transition.

- This reduces the amount of torque required to extrude filament and reduces the likelihood of jamming.

- Reduce the radiator length, thickness and diameter (shorter lengths help to increase the stability of the hot end), while increasing the number of heat sink, making the heat end while reducing weight, have better thermal performance and stability .

- Change the bulky external rotation pneumatic fittings for the catheter cards further reduce weight and reduce the hotend length, but also to the feed deeper, feeding more powerful (pneumatic connectors can only be inserted a short feed pipe, is easily lead feed is not smooth and so on).

- To improve the original heating block, look more simple and practical. Heating pipe, thermistor and aluminum block are fuller contact, so that the temperature control is more precise outstanding.

- All Metal Heat Break, allows for higher extruder temperature extending over 260°C which was limited by PTFE tube

for assembly instruction: contact support@tskamath.com or sms ur email id on whatsapp +91 82174 87594 along with the item ordered

Reviews

There are no reviews yet.